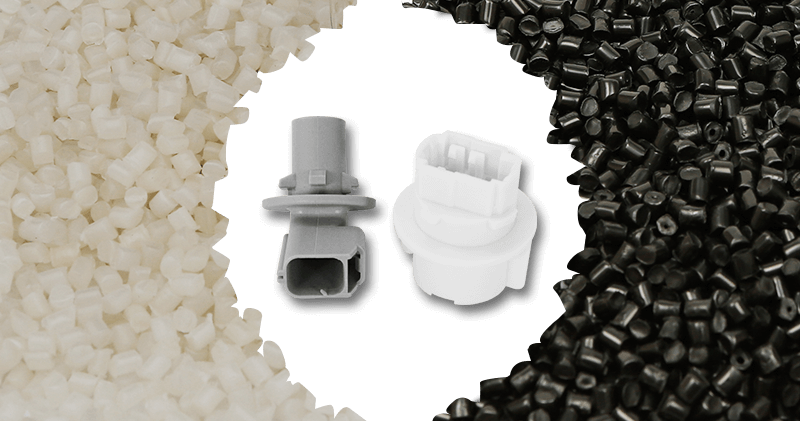

Ocean Plastic

General Grade

Raw materials without adding any reinforcements

Our ocean plastic is a raw materials made from discarded fishing nets without adding any reinforcements.

The general grade PA6 is suitable for industrial part production, such as Buckle pull ring, Baby Strollers, Electrical and electronic parts, Information technology equipment parts, Tool housing, Sports equipment, Gear, Automobiles parts and more.

A2030BK

Material:

Material:

PA6

Specification:

Specification:

General Grade

Color:

Color:

Black

Certification:

Certification:

RoHS、REACH、GRS、UL

Package:

Package:

25kg

Property:

Property:

Low viscosity, can be used for the molding of finish molds

1. Materials Standard:

| Test Items Property | Test Method | Unit | Vaule |

|---|---|---|---|

| Mechanical Properties | |||

| Tensile Strength | ASTM D638 | Kg/cm2 | 700 |

| Elongation at Break | ASTM D638 | % | > 10 |

| Flexural Strength | ASTM D790 | kg/cm2 | 1200 |

| Flexural Modulus | ASTM D790 | kg/cm2 | 30000 |

|

IZOD Impact, Notched 1/8" 23°C IZOD Impact, Notched 1/8" -30°C |

ASTM D256 | kg-cm/cm |

5 |

|

Hardness Shore D Hardness Rockwell R Scale |

ASTM D2240 ASTM D785 |

- |

78 |

| Thermal | |||

|

Heat Deflection Temperature (18.6kg/cm2 ) |

ASTM D648 | °C | 70 |

| Other | |||

| Shrinkage | ASTM D955 | % | 1.2~1.6 |

| Melt Index | ASTM D1238 | g/10min | > 30 |

| Specific Gravity | ASTM D792 | - | 1.14 |

| Ash Content | ASTM D482 | % | < 2 |

| Equilibrium Moisture Content | ASTM D570 | % | < 0.3 |

| Flammability | UL 94 | 1.6mm | - |

2. Molding Condition:

| Drying | Melt Temp | Inject Press. |

|---|---|---|

| 80~100°C*4HR | 235~260°C | 20kg/cm2 |

Note: Test Conditions: 23℃, 50%RH, 24 hours. The datasheet is for your reference. And the data above will vary as the actual use condition changes.