尼龍66

一般射出級

基本材料無添加任何補強材料

通過GRS認證

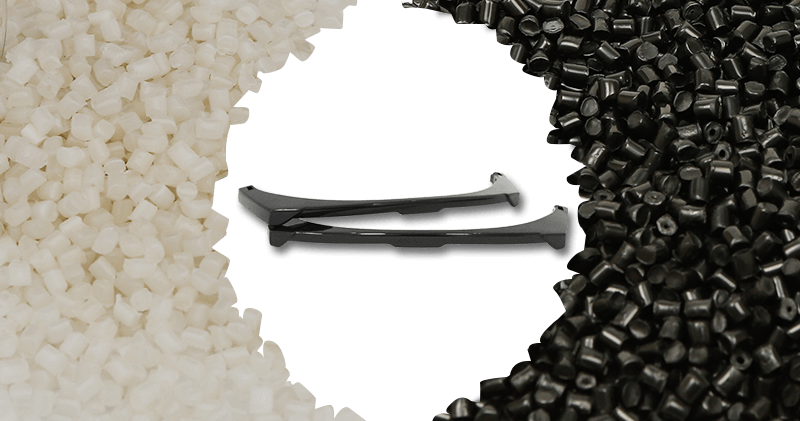

我們的一般級PA66是沒有添加任何增強材料的原料。由於其優異的機械性能、耐化學性和多功能性,它可以廣泛應用於工程熱塑性塑膠。

一般級PA66適合生產洗衣機、嬰兒車零配件、太陽眼鏡、電器零件、工業用零配件等。

B2030NC

材質:

材質:

PA66

規格:

規格:

一般射出級

顏色:

顏色:

本色,提供客製染色服務

認證:

認證:

RoHS、REACH、GRS(Global Recycle Standard)

包裝:

包裝:

25kg

特性:

特性:

低黏度,外表呈現半透明

1. 物性標準:

| 檢測項目 | 測試方法 | 單位 | 數值 |

|---|---|---|---|

| 機械性質 | |||

| 抗張強度 | ASTM D638 | Kg/cm2 | 780 |

| 延伸率 | ASTM D638 | % | > 10 |

| 彎曲強度 | ASTM D790 | kg/cm2 | 1300 |

| 彎曲彈性模數 | ASTM D790 | kg/cm2 | 30000 |

|

IZOD 衝擊, 缺口 1/8" 23°C IZOD 衝擊, 缺口 1/8" -30°C |

ASTM D256 | kg-cm/cm |

6 |

|

蕭氏硬度 洛氏硬度 |

ASTM D2240 ASTM D785 |

- |

80 |

| 熱特性 | |||

| 熱變形溫度(18.6kg/cm2) | ASTM D648 | °C | 85 |

| 其它 | |||

| 收縮率 | ASTM D955 | % | 1.2~1.6 |

| 熔融指數 | ASTM D1238 | g/10min | 90~120 |

| 比重 | ASTM D792 | - | 1.14 |

| 灰份 | ASTM D482 | % | < 1 |

| 含水率 | ASTM D570 | % | < 0.3 |

| 耐燃性 | UL 94 | 1.6mm | - |

2.成形條件:

| 乾燥條件 | 料管溫度 | 射出壓力 |

|---|---|---|

| 80~100°C*4HR | 245~280°C | 20kg/cm2 |

附註:測試條件: 23℃, 50%RH, 24小時。以上數據會隨使用條件不同而有所改變,故此數據僅供參考。

相關應用領域

華司、嬰兒車、電器電子零件、資訊設備零件、工具外殼 、運動器材、齒輪、汽車零件。

B2030SD

材質:

材質:

PA66

規格:

規格:

一般射出級

顏色:

顏色:

白色,提供客製染色服務

認證:

認證:

RoHS、REACH、GRS(Global Recycle Standard)

包裝:

包裝:

25kg

特性:

特性:

低黏度,外表呈現白色

1. 物性標準 :

| 檢測項目 | 測試方法 | 單位 | 數值 |

|---|---|---|---|

| 機械性質 | |||

| 抗張強度 | ASTM D638 | Kg/cm2 | 730 |

| 延伸率 | ASTM D638 | % | > 10 |

| 彎曲強度 | ASTM D790 | kg/cm2 | 1200 |

| 彎曲彈性模數 | ASTM D790 | kg/cm2 | 29000 |

|

IZOD 衝擊, 缺口 1/8" 23°C IZOD 衝擊, 缺口 1/8" -30°C |

ASTM D256 | kg-cm/cm |

5 |

|

蕭氏硬度 洛氏硬度 |

ASTM D2240 ASTM D785 |

- |

80 |

| 熱特性 | |||

| 熱變形溫度(18.6kg/cm2) | ASTM D648 | °C | 85 |

| 其它 | |||

| 收縮率 | ASTM D955 | % | 1.2~1.6 |

| 熔融指數 | ASTM D1238 | g/10min | 70~250 |

| 比重 | ASTM D792 | - | 1.14 |

| 灰份 | ASTM D482 | % | < 1 |

| 含水率 | ASTM D570 | % | < 0.3 |

| 耐燃性 | UL 94 | 1.6mm | - |

2. 成形條件:

| 乾燥條件 | 料管溫度 | 射出壓力 |

|---|---|---|

| 80~100°C*4HR | 245~280°C | 20kg/cm2 |

附註:測試條件: 23℃, 50%RH, 24小時。以上數據會隨使用條件不同而有所改變,故此數據僅供參考。

相關應用領域

華司、嬰兒車、電器電子零件、資訊設備零件、工具外殼 、運動器材、齒輪、汽車零件。

B2040BK

材質:

材質:

PA66

規格:

規格:

一般射出級

顏色:

顏色:

黑色

認證:

認證:

RoHS、REACH、GRS(Global Recycle Standard)

包裝:

包裝:

25kg

特性:

特性:

低黏度,可做於鏡面的模具

1. 物性標準:

| 檢測項目 | 測試方法 | 單位 | 數值 |

|---|---|---|---|

| 機械性質 | |||

| 抗張強度 | ASTM D638 | Kg/cm2 | 680 |

| 延伸率 | ASTM D638 | % | > 2 |

| 彎曲強度 | ASTM D790 | kg/cm2 | 1200 |

| 彎曲彈性模數 | ASTM D790 | kg/cm2 | 28500 |

|

IZOD 衝擊, 缺口 1/8" 23°C IZOD 衝擊, 缺口 1/8" -30°C |

ASTM D256 | kg-cm/cm |

5 |

|

蕭氏硬度 洛氏硬度 |

ASTM D2240 ASTM D785 |

- |

80 |

| 熱特性 | |||

| 熱變形溫度(18.6kg/cm2) | ASTM D648 | °C | 85 |

| 其它 | |||

| 收縮率 | ASTM D955 | % | 1.2~1.6 |

| 熔融指數 | ASTM D1238 | g/10min | 70~250 |

| 比重 | ASTM D792 | - | 1.14 |

| 灰份 | ASTM D482 | % | < 2 |

| 含水率 | ASTM D570 | % | < 0.3 |

| 耐燃性 | UL 94 | 1.6mm | - |

2. 成形條件:

| 乾燥條件 | 料管溫度 | 射出壓力 |

|---|---|---|

| 80~100°C*4HR | 245~280°C | 20kg/cm2 |

附註:測試條件: 23℃, 50%RH, 24小時。以上數據會隨使用條件不同而有所改變,故此數據僅供參考。

B4040BK

材質:

材質:

PA66

規格:

規格:

一般射出級

顏色:

顏色:

黑色

認證:

認證:

RoHS、REACH、GRS(Global Recycle Standard)

包裝:

包裝:

25kg

特性:

特性:

低黏度,可做於咬花的模具

1. 物性標準:

| 檢測項目 | 測試方法 | 單位 | 數值 |

|---|---|---|---|

| 機械性質 | |||

| 抗張強度 | ASTM D638 | Kg/cm2 | 600 |

| 延伸率 | ASTM D638 | % | > 2 |

| 彎曲強度 | ASTM D790 | kg/cm2 | 1100 |

| 彎曲彈性模數 | ASTM D790 | kg/cm2 | 25000 |

|

IZOD 衝擊, 缺口 1/8" 23°C IZOD 衝擊, 缺口 1/8" -30°C |

ASTM D256 | kg-cm/cm |

4 |

|

蕭氏硬度 洛氏硬度 |

ASTM D2240 ASTM D785 |

- |

80 |

| 熱特性 | |||

| 熱變形溫度(18.6kg/cm2) | ASTM D648 | °C | 85 |

| 其它 | |||

| 收縮率 | ASTM D955 | % | 1.2~1.6 |

| 熔融指數 | ASTM D1238 | g/10min | > 150 |

| 比重 | ASTM D792 | - | 1.15 |

| 灰份 | ASTM D482 | % | < 5 |

| 含水率 | ASTM D570 | % | < 0.3 |

| 耐燃性 | UL 94 | 1.6mm | - |

2. 成形條件:

| 乾燥條件 | 料管溫度 | 射出壓力 |

|---|---|---|

| 80~100°C*4HR | 245~280°C | 20kg/cm2 |

附註:測試條件: 23℃, 50%RH, 24小時。以上數據會隨使用條件不同而有所改變,故此數據僅供參考。

相關應用領域

華司、嬰兒車、電器電子零件、資訊設備零件、工具外殼、運動器材、齒輪、汽車零件。